Delhi

- GST NO. : 04AAQPC5123L1ZS

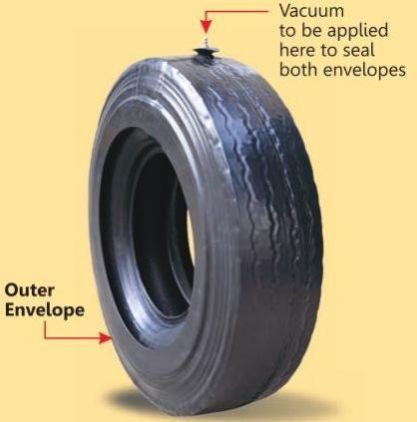

Outer Curing Envelopes

Leading Exporters, Wholesaler of Double Seal Outer Curing Envelope, Flex Seal Outer Curing Envelope, Full Skirt Outer Curing Envelope and Half Skirt Outer Curing Envelope from Delhi.

MOQ : 10 Piece

| Business Type | Exporter, Supplier |

| Size | Standard |

| Type | Double Seal |

| Material | Rubber |

| Shape | Round |

| Application | Automobile Industry |

| Color | Black |

| Country of Origin | India |

Preferred Buyer From

| Location | Worldwide |

Install the envelope and make sure it is centered and straight on the tyre and the valve is over the wicking pad. Lubrication increases envelope life and keeps the envelope from sticking to cushion gum, splices or the tyre casing.

Apply lubricant when you experience sticking, while the envelope is still hot. Rotate envelopes so that a hot envelope is allowed to cool between cures.

MOQ : 10 Piece

| Business Type | Exporter, Supplier |

| Size | Standard |

| Type | Flex Seal |

| Material | Rubber |

| Shape | Round |

| Application | Automobile Industry |

| Color | Black |

| Pattern | Plain |

| Country of Origin | India |

Preferred Buyer From

| Location | Worldwide |

MOQ : 10 Piece

| Business Type | Exporter, Supplier |

| Type | Full Skirt |

| Material | Rubber |

| Application | Automobile Industry |

| Color | Black |

| Country of Origin | India |

| Pattern | Plain |

Preferred Buyer From

| Location | Worldwide |

Features :

- Install the envelope and make sure it is centered and straight on the tyre and the valve is over the wicking pad.

- Lubrication increases envelope life and keeps the envelope from sticking to cushion gum, splices or the tyre casing. Apply lubricant when you experience sticking, while the envelope is still hot.

- Rotate envelopes so that a hot envelope is allowed to cool between cures.

MOQ : 10 Piece

| Business Type | Exporter, Supplier |

| Type | Half Skirt |

| Material | Rubber |

| Application | Automobile Industry |

| Color | Black |

| Country of Origin | India |

| Pattern | Plain |

Preferred Buyer From

| Location | Worldwide |

Features :

- To prevent envelope burst: 2" wicking tapes should be applied at 4 places for proper air bleeding between tyre and envelope. Wicking tape should protrude outside the envelope.

- Pre-inflate the tyres to between 20-30 psi to avoid distortion of the casing caused by the weight of the lid of the tread bonder.

- Maintain the differential pressure of 30 psi between steam pressure and tube air pressure especially at the end of the curing process.